Agilitech: Product Development, Industrial Design, 3D and 360º Visualization

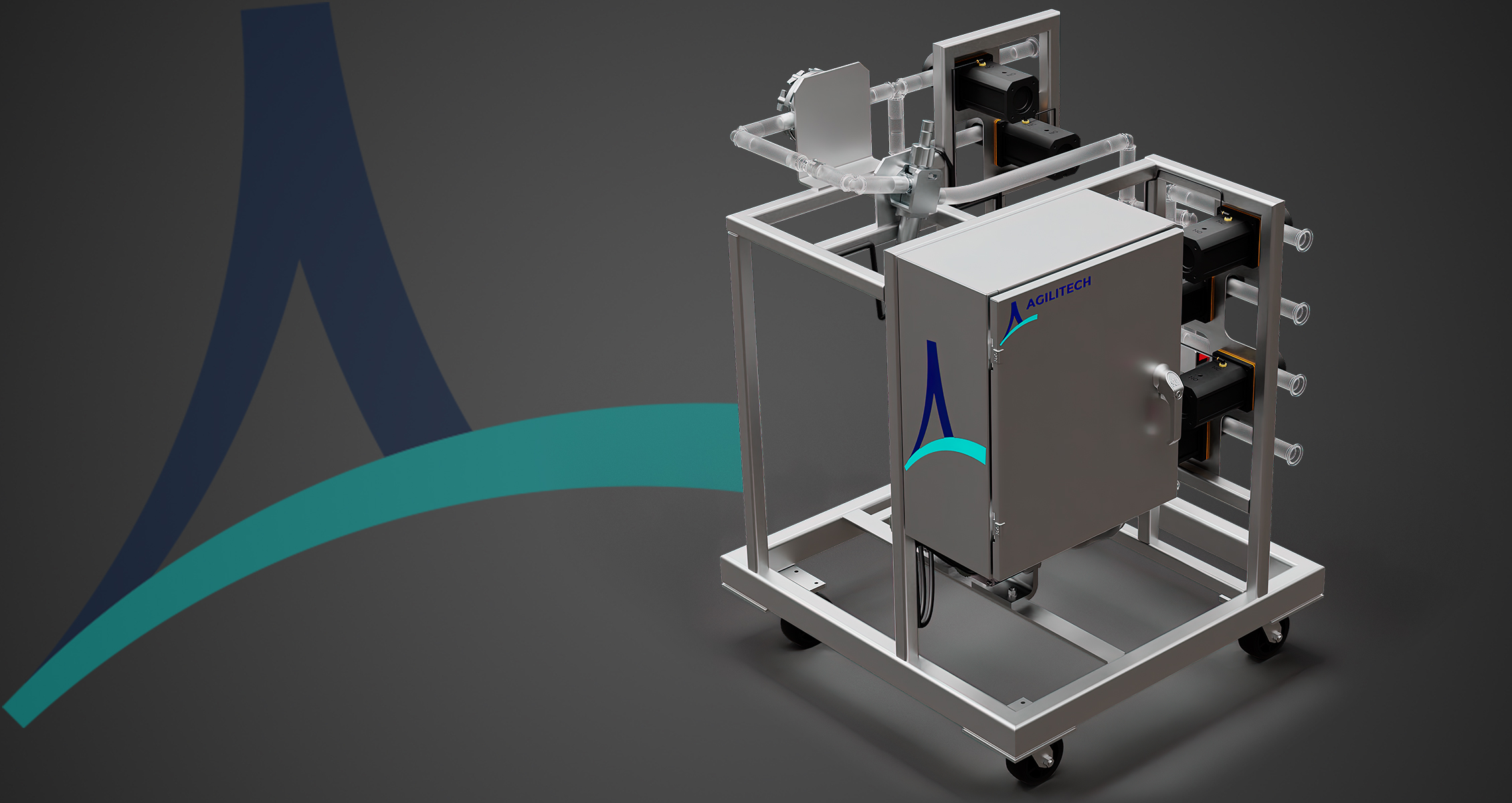

In just 18 months, Agilitech went from startup to industry leader in single-use technology for bioprocessing. This rapid success was fueled by a unique combination of innovative product development, collaborative industrial design, and cutting-edge 3D visualization.

A Transformed Approach

Agilitech challenged the traditional approach to product design and engineering. Instead of creating generic systems and expecting clients to adapt, they prioritized flexibility and collaboration.

1. Customer-Centric Design:

Front-End Planning: Agilitech invests time upfront to understand each client’s specific needs and future goals. They don’t offer “off-the-shelf” solutions; they design systems that fit your unique process.

Iterative Design Process: Agilitech works closely with you through an iterative process to model a solution that meets your current and future needs. This collaborative approach ensures the final product perfectly matches your requirements.

2. Unmatched Design Flexibility:

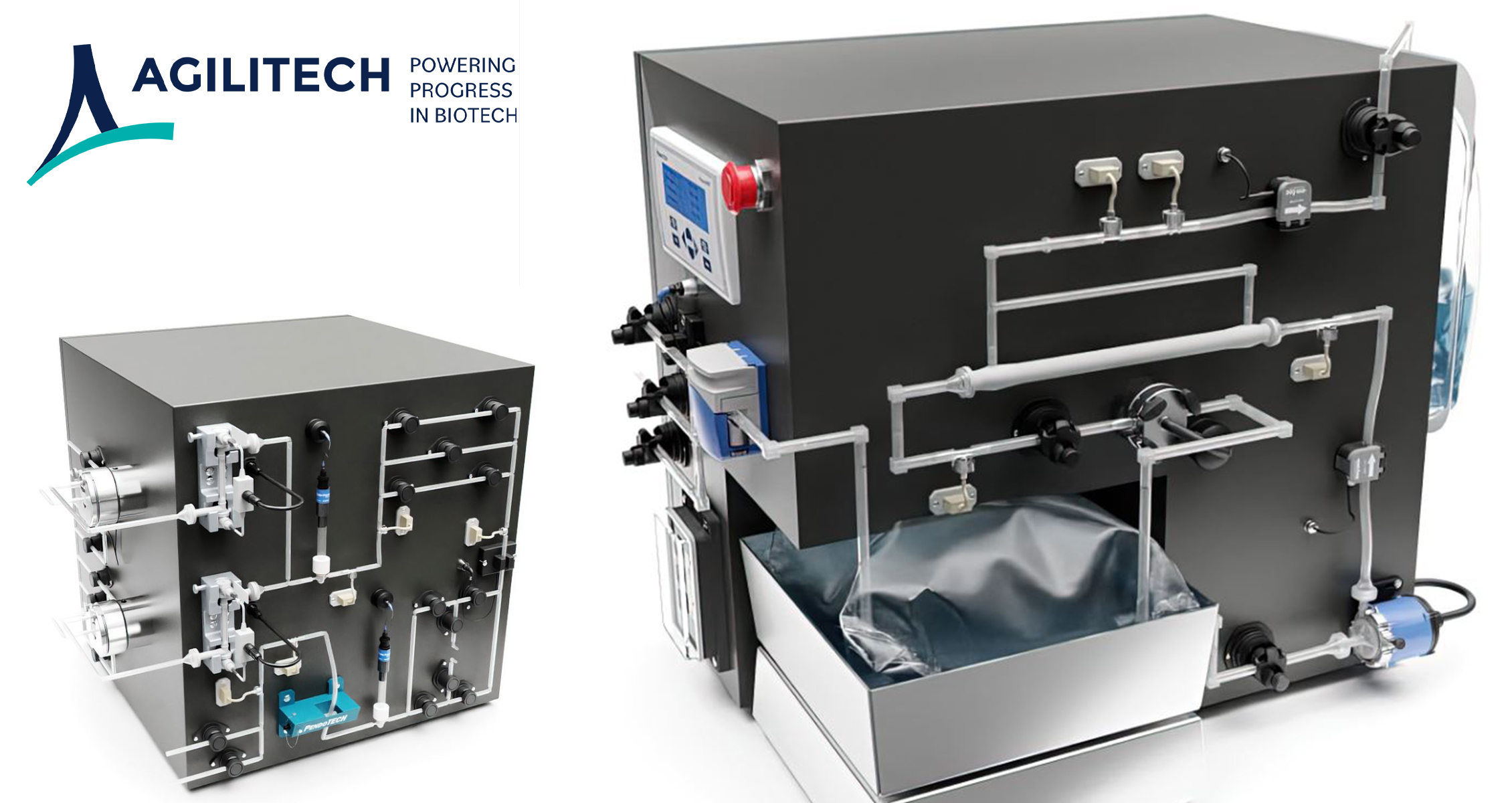

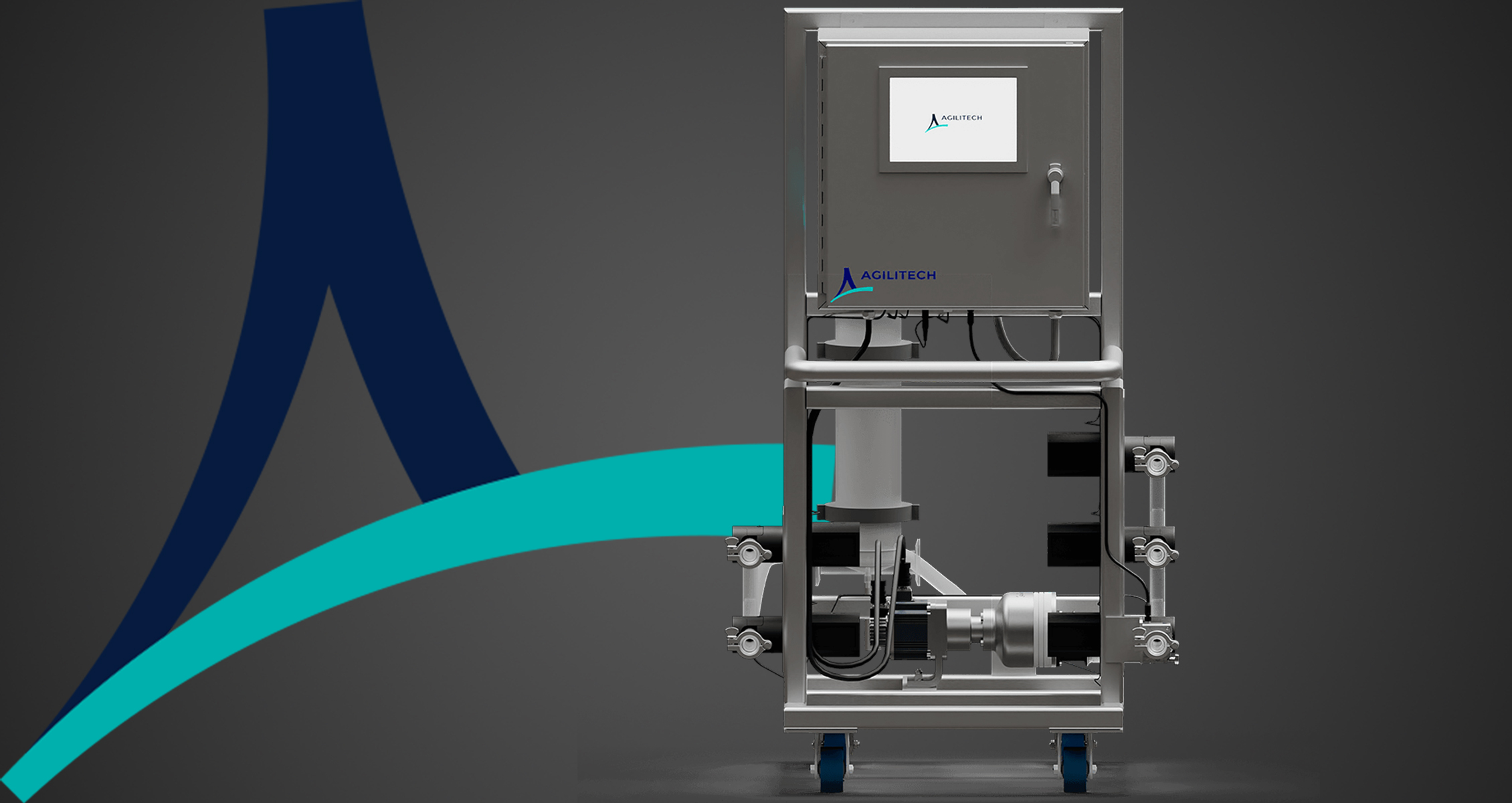

Modular Design: Agilitech systems allow modifications of core components. You can add filters, outlets, buffers, adapt filter sizes, and more—all within the same system.

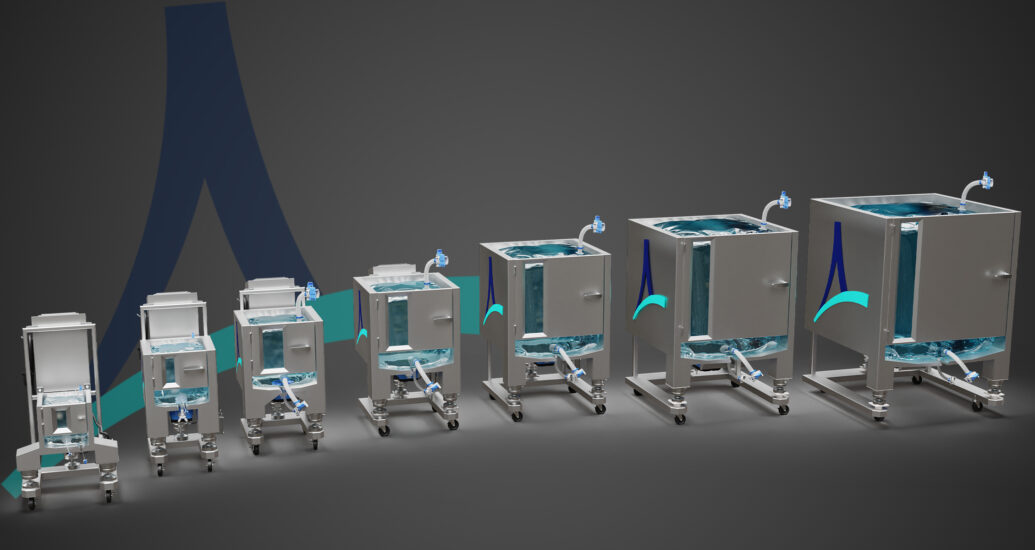

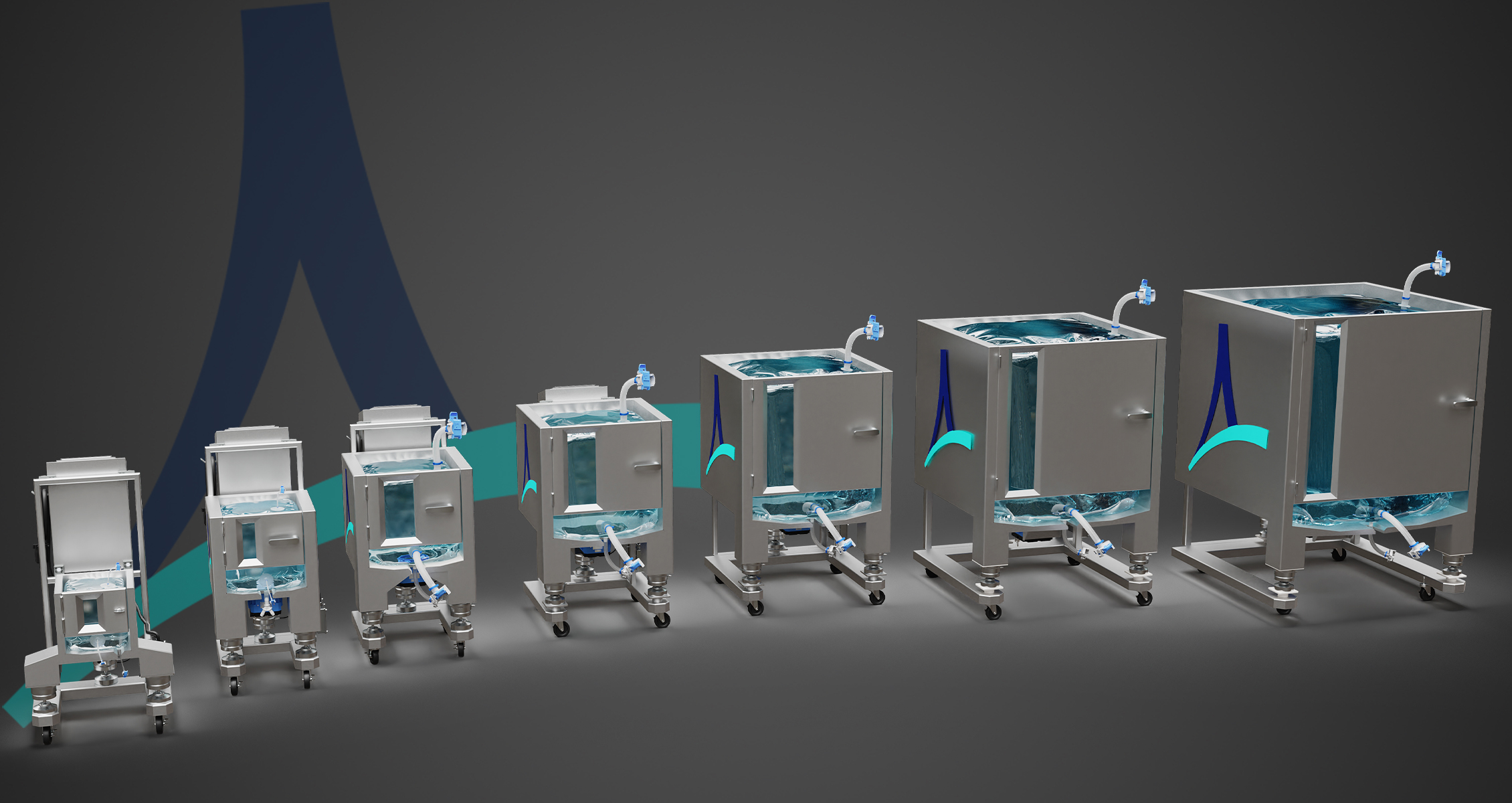

Scalability: Their systems seamlessly scale from lab to pilot to full-scale production, eliminating the need for multiple purchases as your process grows. This patent-pending technology streamlines scale-up and reduces costs.

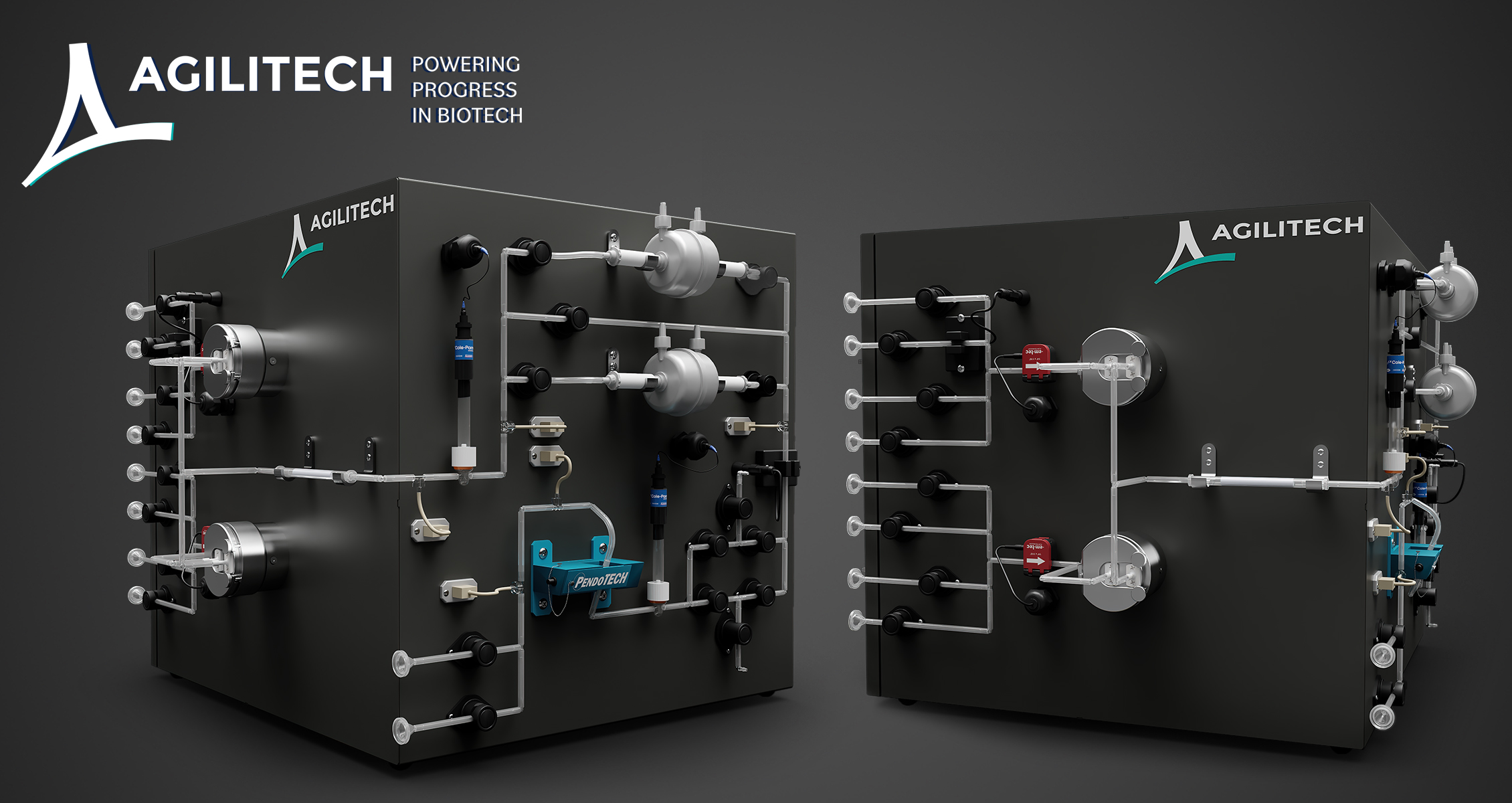

3. Brand-Agnostic Approach:

Integrate Your Preferred Brands: Agilitech uses best-in-class filters and components from various brands, allowing you to leverage your existing preferences.

No Vendor Lock-in: This flexibility provides you with greater control and the ability to switch components if needed, offering peace of mind in a dynamic market.

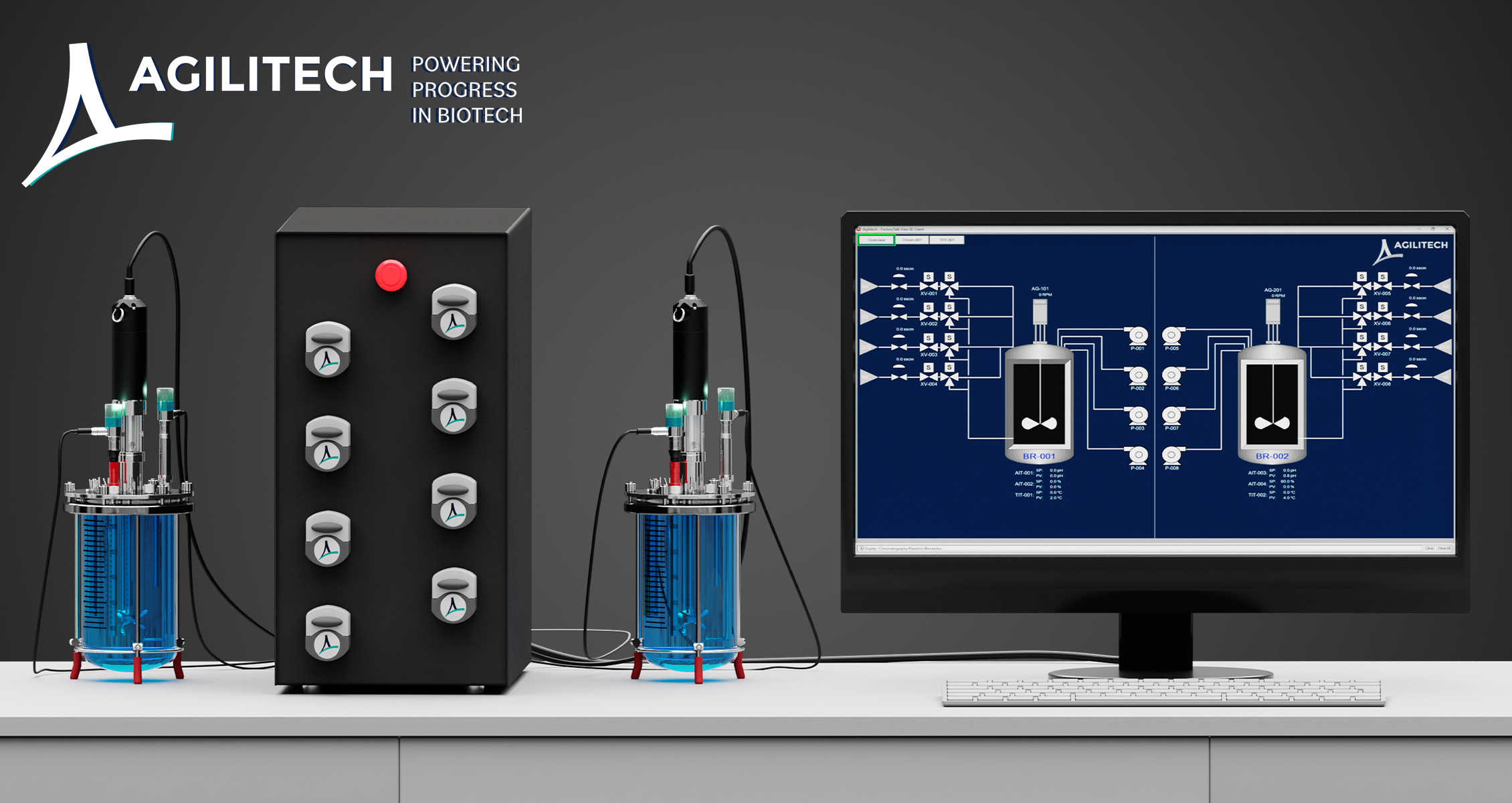

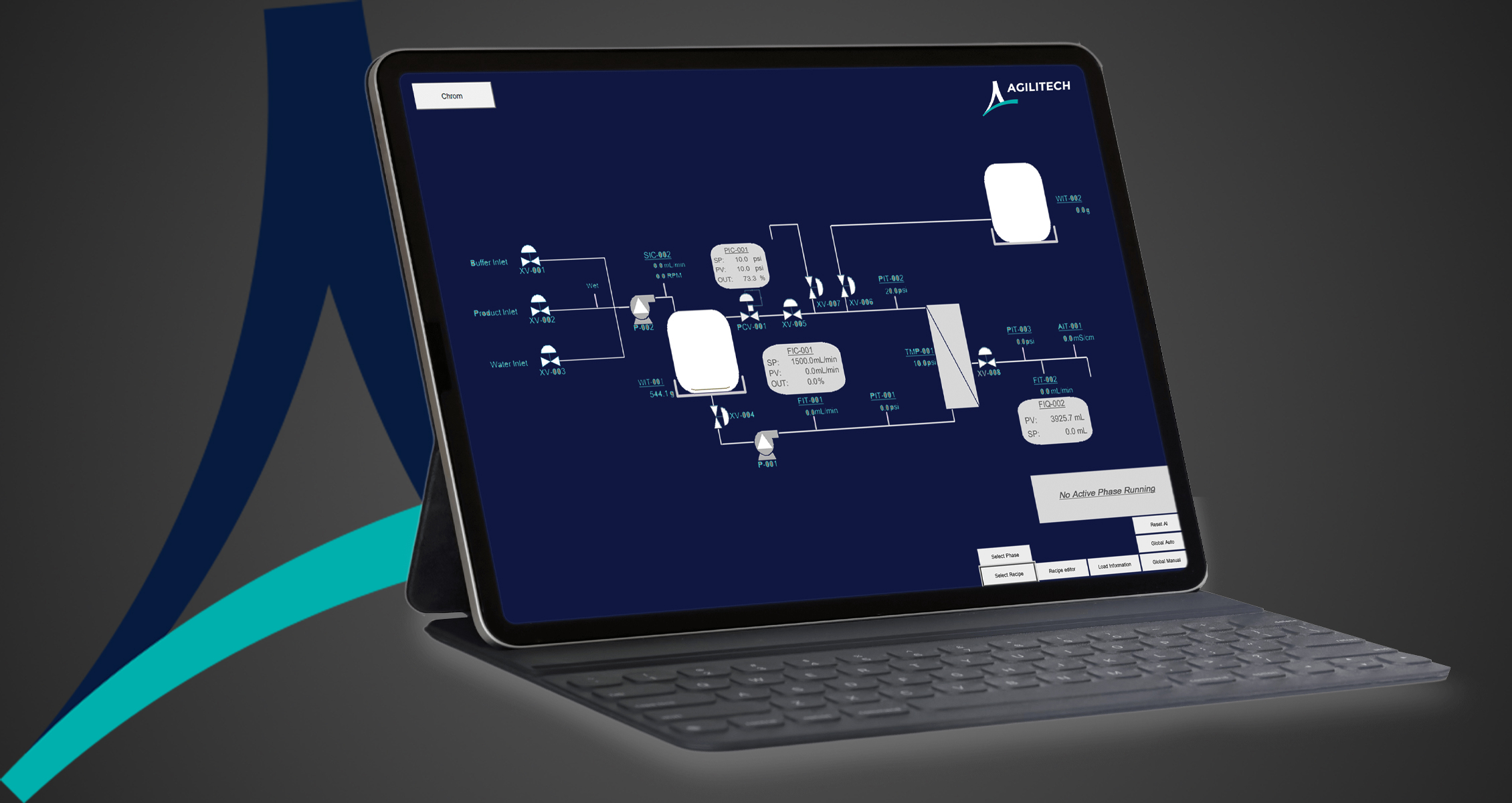

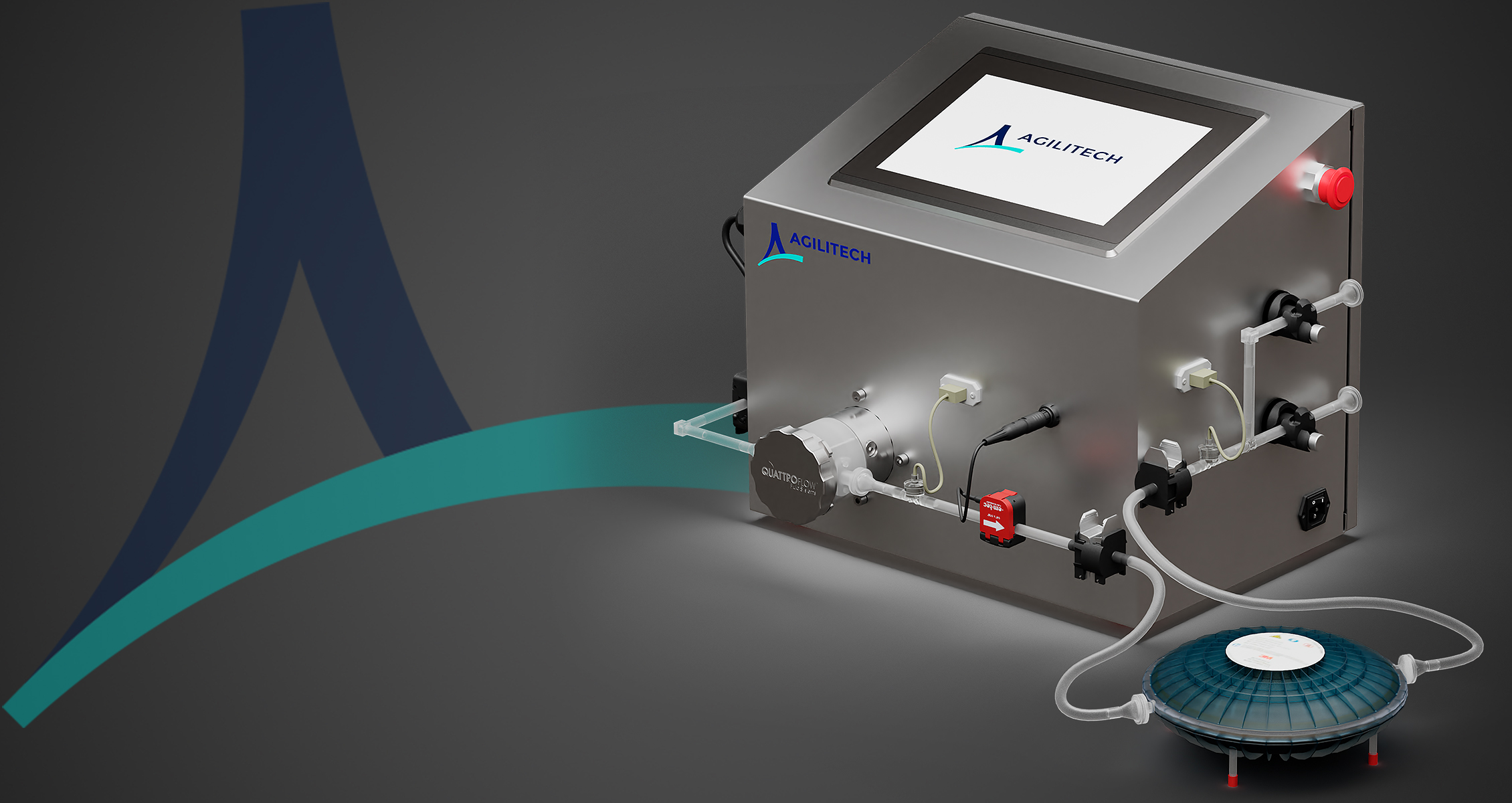

4. Automation and Control Integration:

ISA S88 Compliance: Their ISA-88 comn, giving you complete control over your process.

Platform Adaptability: Integrate Agilitech systems with any modern automation and control platform – DeltaV, Rockwell Automation, or your preferred choice. Their team ensures seamless integration with your existing infrastructure.

5. World-Class Service and Support:

Quality Manufacturing: All systems are built to the highest standards and delivered with comprehensive documentation, including FAT, SAT, IQ, and OQ testing.

Preventative Maintenance: Agilitech provides a preventative maintenance plan and spare parts list to ensure optimal system performance. They also offer on-site preventative maintenance services.

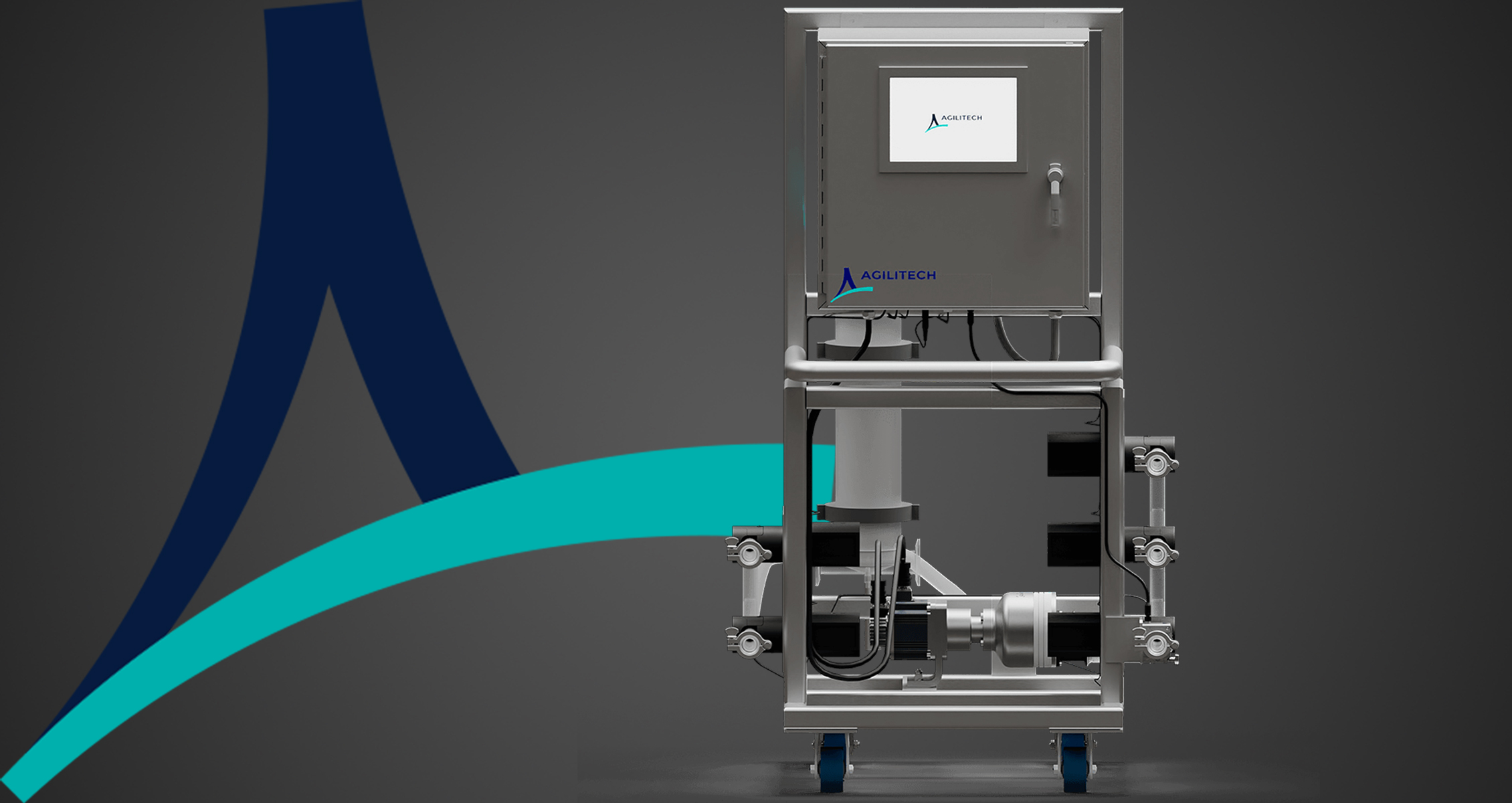

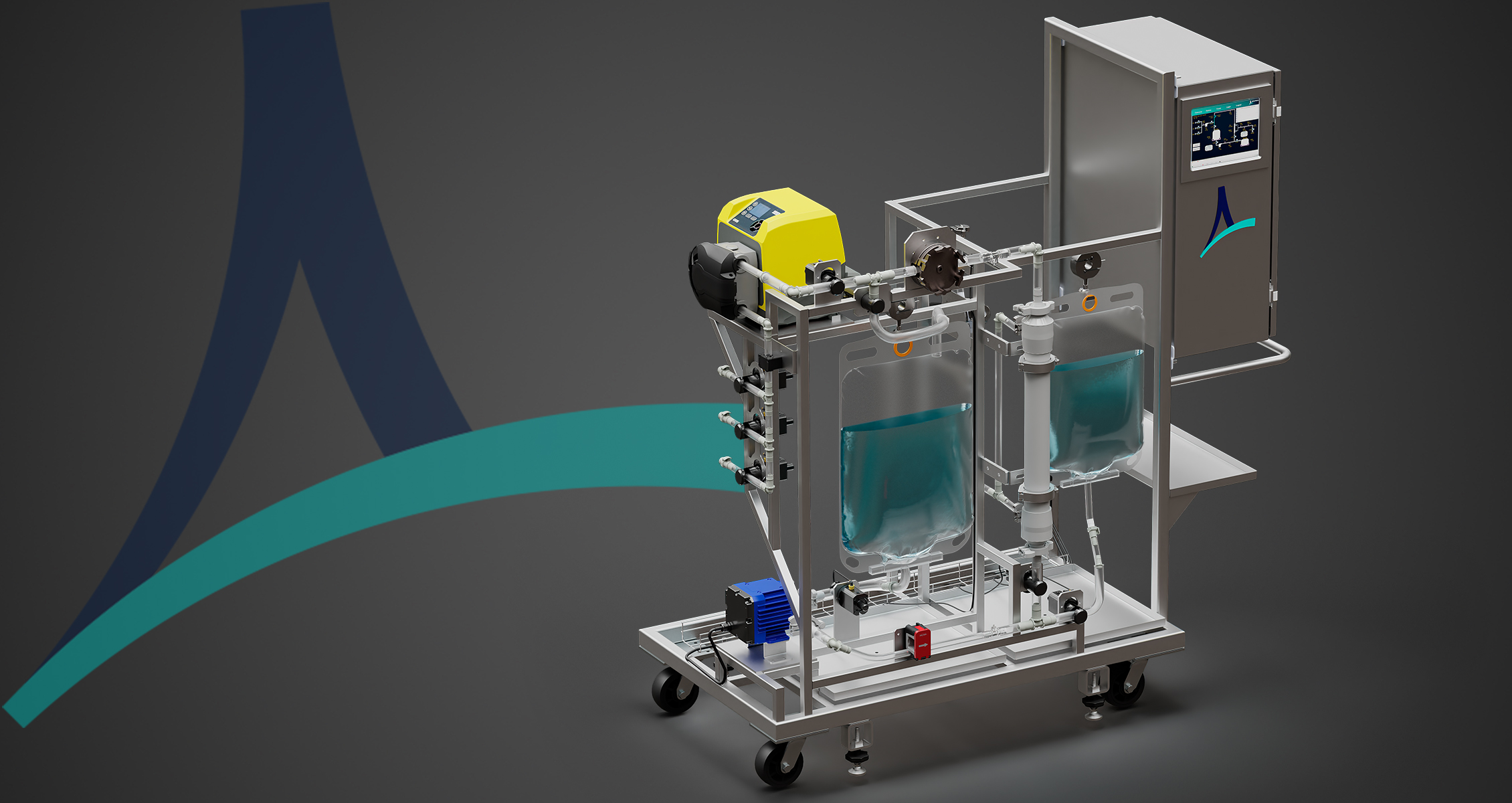

3D Visualization: Bringing Ideas to Life

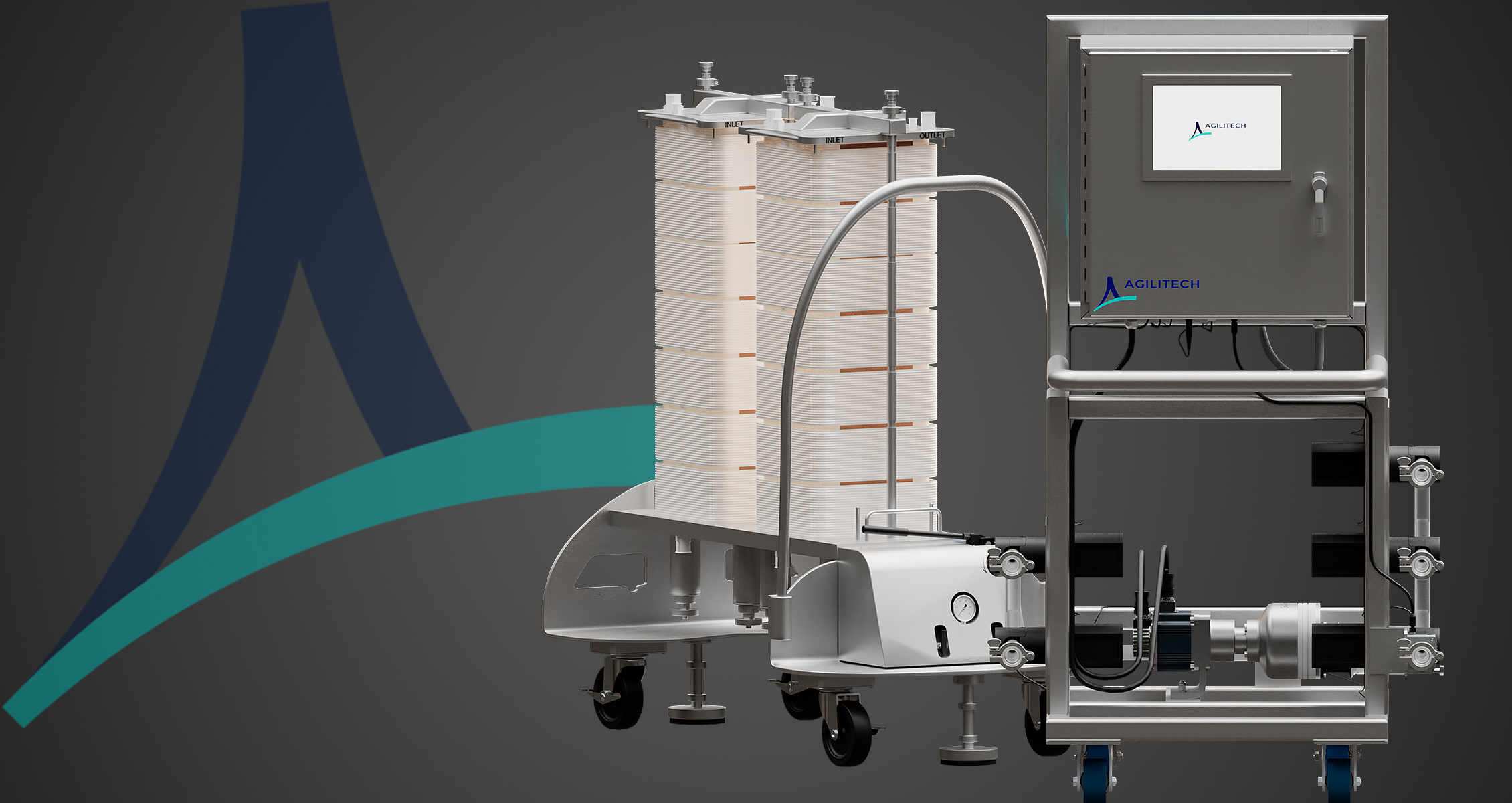

Agilitech utilizes state-of-the-art 3D rendering and 360° view technology to visualize product designs. This allows clients to fully understand the system’s layout, functionality, and integration within their existing infrastructure. This interactive approach facilitates decision-making and ensures all stakeholders are aligned.

The Result: Success Story in Bioprocessing

By putting the client at the center of its design and manufacturing process, Agilitech has revolutionized the single-use technology market. Its innovative products, paired with exceptional service and support, have made it a trusted partner for leading biopharmaceutical companies worldwide.

Conclusion

Agilitech’s dedication to flexibility, collaboration, and cutting-edge technology has propelled them to the forefront of the bioprocessing industry. They continue to push boundaries and develop innovative solutions that empower researchers and manufacturers to advance scientific progress and improve lives.

Single-Use Systems That Are Redefining Flexibility In Bioprocessing

The benefits of single-use technologies in bioprocessing are well-known and include time savings, increased process flexibility, reduced risk of cross-contamination, easy disposal, and other operational efficiencies. Agilitech single-use technologies are designed to provide all of these benefits—and much more.

A wide range of scalable single-use solutions for research to pilot and full-scale production

Agilitech single-use systems maximize process efficiencies, reduce cost, and accelerate drug development as well as production. Our bioprocessing solutions include single-use chromatography systems and a full range of single-use filtration solutions, including sterile filtration, depth filtration, virus filtration, and tangential flow filtration (TFF) systems. We also offer custom-tailored bioprocess controllers for lab and production environments. For more information about specific Agilitech single-use products, click the links at the right.

A revolutionary approach to product design and engineering

A transformative product design and engineering process is what makes Agilitech single-use products unique and ensures they meet the exact needs of each and every customer.

Our unique collaborative front-end planning and product design process starts with you. We invest the time upfront to understand your current needs and future development goals before adapting our standard single-use technologies to fit your purpose.

Agilitech’s product development team works through an iterative design process with you to model a single-use product solution that meets your current and future process needs. Based on that custom-tailored design, we provide a proposal for the best-fit solution along with options for support services. Once you approve the design model, we move swiftly to build your system. Standard Factory Acceptance Testing (FAT) and system qualification (IQ/OQ) are performed before the system leaves our facility to streamline delivery and ensure it is ready for use upon installation.

Agilitech Single-Use Bioprocessing Products:

- Bioreactor Controllers:

- For stirred-tank vessels up to 20 L

- For rockers up to 50 L

- Bioreactor Controllers:

- Flexible and Compact Dual Bioreactor Controller

- Flexible Bioprocess Controller for Single-Use Bioreactors Up To 2000 L

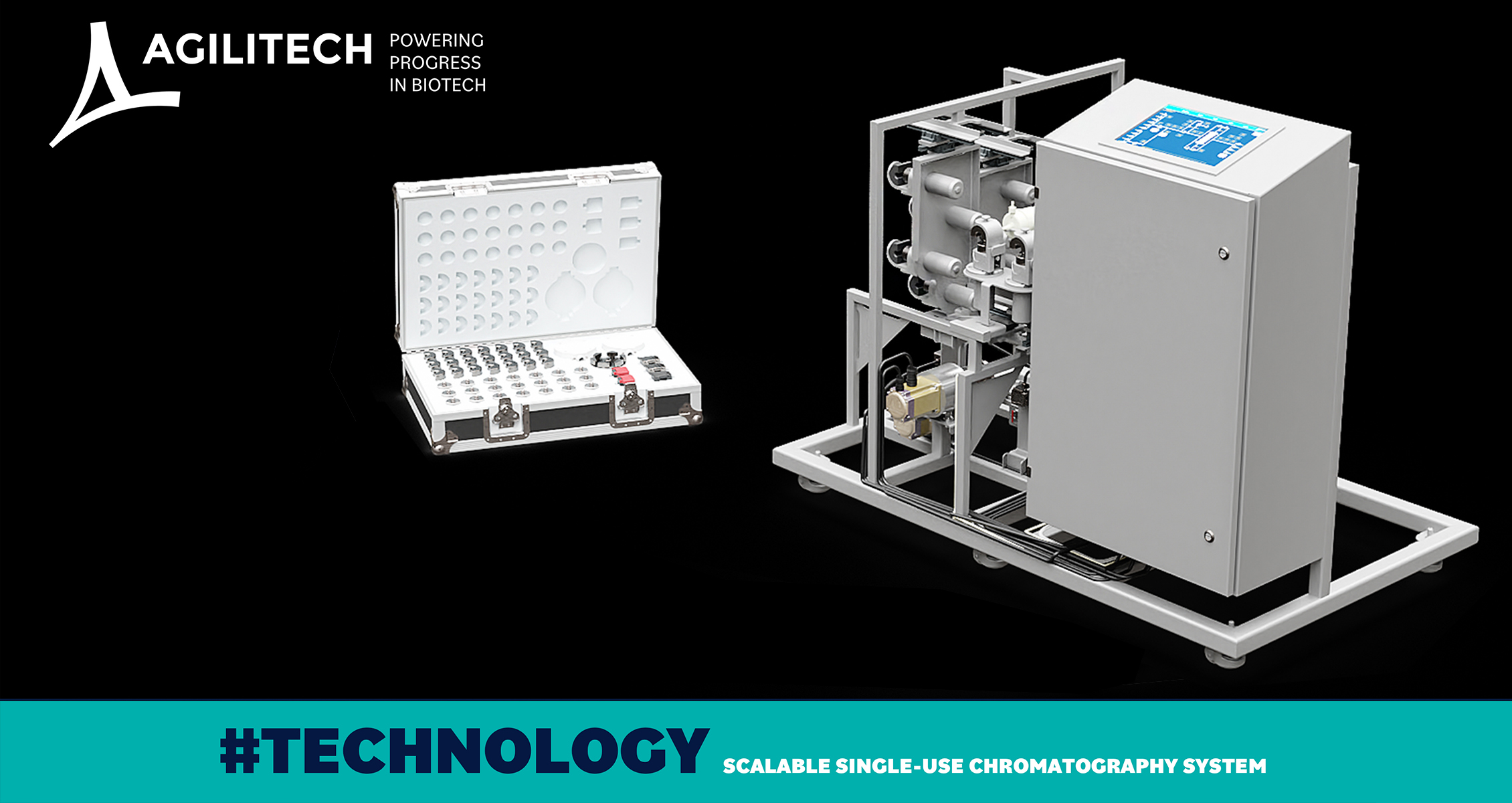

- Chromatography Systems: Benchtop models up to 3.1 LPM flow

- Chromatography Systems: Floor-standing models up to 41 LPM flow

- Scalable Chromatography System: Configurable for 0.25 and 0.50-inch tubing Up to 15 LPM flow

- Depth Filtration Systems: Inline Dilution Systems

- Mixers

- Multipurpose Filtration Systems

- Sterile Filtration

- Depth Filtration

- Virus Filtration

- Sterile Filtration System

10. Tangential Flow Filtration Systems: Benchtop models up to 7.7 LPM flow

11. Tangential Flow Filtration Systems: Floor-standing models up to 100 LPM flow

12. Virus Filtration Systems